Comprehensive Overview of Cut-Resistant Safety Gloves

What Exactly Are Cut-Resistant Safety Gloves and Why Are They Crucial?

Cut-resistant safety gloves in London are meticulously designed to offer protection for hands against cuts and lacerations across various work settings. These gloves are indispensable components of personal protective equipment (PPE) and serve a vital function in safeguarding individuals in high-risk sectors such as construction, manufacturing, and food processing. In these environments, the likelihood of hand injuries caused by sharp tools and materials is significantly heightened. Constructed from advanced materials, these gloves not only provide enhanced durability but also deliver essential cut protection, allowing workers to handle sharp instruments and materials with confidence, thereby reducing the risk of injury.

Employers are progressively recognising the importance of supplying their workforce with dependable cut-resistant gloves, which greatly contributes to cultivating a safer workplace environment. Implementing such protective measures leads to a noticeable reduction in workplace accidents and health-related claims. The design of these gloves is thoughtfully crafted to strike a balance between comfort, dexterity, and safety, enabling workers to fulfil their duties effectively without sacrificing protection.

Exploring the Diverse Selection of Cut-Resistant Gloves Available

A broad range of cut-resistant gloves is readily available in the marketplace, each designed to cater to specific protection requirements and comfort levels. The most commonly utilised materials in the manufacture of these gloves include Kevlar, Dyneema, and stainless steel mesh.

Kevlar gloves are celebrated for their exceptional cut resistance and durability, making them a preferred option for demanding tasks such as construction and metal fabrication. In contrast, Dyneema gloves are known for their comfort and flexibility, rendering them ideal for jobs requiring precise handling without compromising safety. These gloves are particularly favoured in the food processing sector where dexterity is paramount. Lastly, stainless steel mesh gloves offer unparalleled cut resistance, although they may limit dexterity somewhat. These are typically used in settings where workers deal with sharp materials, such as butchery and glass manufacturing.

Selecting the appropriate type of cut-resistant glove is primarily influenced by the specific hazards present in the workplace, along with individual preferences regarding comfort and fit.

Why Are Cut-Resistant Gloves Indispensable in the Workplace?

The importance of cut-resistant gloves extends across various industries, and their influence cannot be overlooked. Workplace injuries pose not only physical threats but also substantial financial repercussions. Utilising cut-resistant gloves is fundamental in bolstering overall safety. In the UK, regulatory bodies stress the importance of complying with health and safety regulations, which necessitate the use of suitable PPE, including cut-resistant gloves.

Employers who equip their teams with these gloves not only protect their employees' health but also foster a culture of safety that can enhance employee morale and productivity. The adoption of cut-resistant gloves can dramatically lower the likelihood of accidents, which may lead to costly downtime and medical expenses. By investing in protective gear, organisations can effectively manage risks while ensuring compliance with relevant regulations.

How Can You Choose the Most Appropriate Cut-Resistant Gloves?

Selecting the right cut-resistant gloves necessitates careful evaluation of several critical factors tailored to the specific demands of the job. First and foremost, understanding the required level of cut resistance is crucial. Different tasks demand varying degrees of protection, and familiarising yourself with the EN 388 standard can significantly assist in making an informed selection. The EN 388 standard evaluates gloves based on their resistance to cuts, punctures, tearing, and abrasion.

- A: No cut resistance (not rated)

- B: 1.2 to 1.5 cut resistance

- C: 1.5 to 2.2 cut resistance

- D: 2.2 to 3.0 cut resistance

- E: 3.0 to 4.0 cut resistance

- F: Over 4.0 cut resistance

Next, the choice of material is paramount to the glove's performance. While Kevlar delivers robust cut resistance, Dyneema offers a lighter, more comfortable alternative. Assessing the work environment—such as the types of sharp objects handled and the required level of dexterity—is vital for selecting the appropriate material.

Lastly, ensuring a proper fit is essential for achieving optimal performance. Gloves should fit snugly yet allow for sufficient movement. Trying on different sizes and brands can assist individuals in finding the best fit for their hands, ultimately enhancing both safety and comfort during use.

Essential Maintenance Practices for Cut-Resistant Gloves

Proper maintenance of cut-resistant gloves is crucial for extending their lifespan and preserving their protective capabilities. Regular cleaning is essential, as accumulated dirt, grease, and chemicals can deteriorate materials and diminish their effectiveness. Most gloves come with specific cleaning instructions; adhering to these guidelines can help maintain their structural integrity.

Moreover, regularly inspecting gloves for wear and tear is vital. Conducting frequent checks for signs of damage, such as cuts, frays, or punctures, allows users to replace gloves before they lose their protective qualities. Adequate storage is equally important; gloves should be kept in a cool, dry place away from direct sunlight, as prolonged exposure can weaken materials over time.

Safety experts advocate for a proactive approach to glove maintenance, ensuring they are replaced when significant wear is observed. Understanding common maintenance concerns, such as staining or loss of elasticity, can aid users in determining when it is time to invest in a new pair. Proper care not only maximises the lifespan of cut-resistant gloves but also guarantees ongoing protection for the user.

Where Can You Source Cut-Resistant Safety Gloves in London?

Local Outlets for Trustworthy Safety Equipment

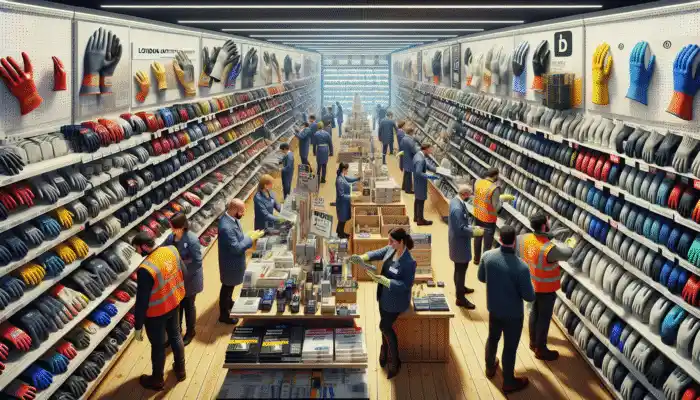

For those looking to purchase cut-resistant safety gloves in London, local safety equipment stores offer a broad selection. These establishments typically stock a wide array of safety gear, including numerous brands and models of cut-resistant gloves. A significant advantage of shopping in-store is the opportunity to receive personalised expert assistance from knowledgeable staff who can guide you in choosing the right gloves for your specific work environment.

In London, well-known safety equipment retailers such as Screwfix and RS Components provide extensive selections and often have staff available to assist with sizing and material inquiries. Additionally, smaller local shops can be found throughout the city, sometimes offering specialised products and personalised services.

Shopping at a local store also allows you to try on gloves before making a purchase, ensuring a suitable fit that enhances comfort and safety. Furthermore, many stores have exchange policies, providing reassurance if the gloves do not meet your expectations upon use.

Online Retailers Focusing on Safety Equipment

In today’s digital age, many consumers prefer the convenience of online shopping for workplace safety equipment, including cut-resistant gloves. Numerous online retailers in London specialise in safety gear, offering a vast selection of gloves from various brands. The primary advantage of online shopping is the ability to browse and compare products from the comfort of your home, saving both time and effort.

Websites such as Amazon UK and eBay showcase extensive inventories, often featuring customer reviews that provide valuable insights into the quality and efficacy of specific gloves. Furthermore, specialist sites like SafetyGloves.co.uk or WorkwearExpress focus exclusively on safety gear, offering detailed product descriptions and specifications to assist in your selection process.

Many online retailers also provide delivery services, making it convenient to have gloves shipped directly to your workplace or home. It is crucial to review the return policies when shopping online, as these can vary significantly. This ensures that users can return gloves that do not meet their expectations or fit properly, thereby guaranteeing they receive the necessary protection.

Industrial Supply Companies: A Key Resource

Industrial supply companies in London serve as a valuable resource for businesses and individuals looking to acquire cut-resistant gloves, especially in bulk. These companies cater to a wide variety of industries, offering high-quality safety gear that complies with stringent standards. Many industrial suppliers maintain established relationships with manufacturers, allowing them to provide competitive pricing and exclusive deals.

Companies such as Weldas UK and Toolstation supply a range of cut-resistant gloves, often featuring bulk purchasing options that can yield significant savings for larger organisations. Additionally, local distributors may offer tailored selections of gloves suitable for specific sectors, from food processing to construction, ensuring customers receive the most appropriate products.

When procuring through industrial supply companies, businesses frequently benefit from expert consultations, enabling them to make well-informed decisions based on the specific hazards their employees face. This personalised service can lead to a better overall fit for both the company’s needs and the safety of its workforce.

Guidelines for Selecting the Ideal Cut-Resistant Gloves

What Level of Cut Resistance Is Required for Your Tasks?

Determining the appropriate level of cut resistance is essential when selecting cut-resistant gloves, as different tasks require varying degrees of protection. Familiarising yourself with the EN 388 standard, which evaluates gloves based on their resistance to cuts, punctures, tearing, and abrasion, can greatly influence your decision.

The EN 388 ratings provide a clear indication of glove performance in terms of cut resistance, with ratings ranging from A (no cut resistance) to F (over 4.0 cut resistance). Selecting gloves with the appropriate rating ensures that workers are adequately shielded from the specific hazards they will encounter. For instance, tasks involving heavy machinery or sharp tools typically necessitate gloves rated D or higher, whereas lighter tasks may only require gloves rated B or C.

By understanding the specific dangers present in your work environment, you can choose gloves that align with your needs. For example, workers in construction or manufacturing settings often handle sharp materials, necessitating higher cut resistance. Conversely, employees in food processing may require gloves that balance cut protection with dexterity for safe food handling.

What Materials Are Most Suitable for Your Needs?

The choice of material plays a critical role in the effectiveness and comfort of cut-resistant gloves. Various materials are available, each offering distinct advantages tailored to specific tasks and environments.

Kevlar is one of the most recognised materials for cut-resistant gloves, known for its high durability and effective cut resistance. It is optimal for environments where heavy-duty protection is essential, such as construction sites or metalworking. In contrast, Dyneema provides a lightweight alternative that excels in flexibility and comfort, making it suitable for tasks requiring precision handling, such as food processing or delicate assembly work.

Additionally, stainless steel mesh gloves offer exceptional cut protection but may sacrifice some dexterity. These gloves are often used in industries that handle sharp objects, such as glass and metal fabrication.

When selecting the right material, consider not only the level of cut resistance required but also the work environment and the need for dexterity. Achieving a balance between protection and comfort is vital for maintaining productivity and safety in the workplace.

How to Ensure an Accurate Fit?

Achieving an accurate fit for cut-resistant gloves is crucial for ensuring both safety and comfort during use. Gloves that fit correctly promote better dexterity and movement, enabling users to perform tasks effectively. To ensure a proper fit, begin by measuring your hand according to the manufacturer’s sizing charts.

It is advisable to try on various sizes and brands, as sizing can differ between manufacturers. Gloves should fit snugly around the fingers and palm without being excessively tight, allowing for natural movement. Additionally, ensure that the gloves are long enough to cover the wrist adequately, providing protection against cuts and lacerations.

Considering specific tasks can guide the selection of glove size and fit. For instance, if tasks require intricate handling or precision, a tighter fit may be preferred. Conversely, for more robust tasks, a slightly looser fit may afford the user greater comfort and flexibility.

Conducting a fit test is important; move your fingers and hands in the gloves while mimicking the tasks you will perform. This helps identify potential discomfort or movement restrictions before finalising a purchase.

Expert Recommendations on Purchasing Cut-Resistant Safety Gloves in London

What Guidance Do Safety Experts Provide?

Safety experts in London consistently underscore the importance of selecting cut-resistant gloves that comply with stringent safety standards while balancing comfort and usability. When choosing gloves, assessing the specific hazards associated with your job is vital. For example, construction sites may present unique challenges, such as handling sharp tools and materials, necessitating gloves with higher cut-resistance ratings.

Experts often advise opting for reputable brands recognised for their quality and adherence to EN 388 standards. Furthermore, local specialists encourage users to familiarise themselves with the particular requirements of their job roles; for instance, butchers in food processing require gloves that not only provide cut protection but also meet hygiene standards to ensure food safety.

Real-world examples from local experts frequently demonstrate how appropriate glove selection can prevent injuries. Numerous studies have indicated that employees who wear cut-resistant gloves correctly experience fewer accidents, resulting in a safer, more productive work environment.

How Should You Maintain and Care for Your Gloves?

Proper maintenance and care of cut-resistant gloves are essential to extend their lifespan and preserve their protective capabilities. Experts recommend that users strictly follow the manufacturer’s cleaning guidelines, as improper cleaning methods can compromise the materials and reduce effectiveness. Regularly cleaning gloves removes accumulated dirt and contaminants that can adversely impact performance.

Inspection is another critical aspect of glove maintenance. Safety experts suggest routinely checking gloves for signs of wear, including cuts, frays, or punctures. Gloves exhibiting significant damage should be replaced immediately to avoid compromising safety.

Furthermore, proper storage is crucial. Gloves should be kept in a cool, dry environment away from direct sunlight, which can weaken materials over time. Adhering to these expert maintenance tips can significantly prolong the life of cut-resistant gloves, ensuring workers remain protected throughout their use.

What Innovations Are Emerging in Cut-Resistant Gloves?

The field of cut-resistant gloves is continually advancing, with innovations enhancing comfort, protection, and usability. Recent developments have introduced new materials that offer superior cut resistance while remaining lightweight and flexible. For example, advancements in synthetic fibres have led to the creation of gloves that combine cut resistance with breathability, increasing comfort for prolonged wear.

Experts in London highlight the growing trend of integrating smart technology into safety gear, including cut-resistant gloves. Some manufacturers now offer gloves equipped with embedded sensors that monitor and report factors such as temperature and grip strength, providing real-time data to enhance workplace safety.

Staying informed about these innovations is crucial for both employers and workers. Engaging with industry publications, attending trade shows, and participating in training sessions can help ensure users remain aware of the latest offerings. By keeping abreast of advancements in cut-resistant gloves, businesses can make informed investment decisions that bolster workplace safety.

What Advantages Do Cut-Resistant Gloves Offer?

Improved Safety in High-Risk Work Environments

The use of cut-resistant gloves significantly enhances safety in environments where sharp objects are prevalent, such as construction sites and food processing facilities. By acting as a protective barrier between the skin and potential hazards, these gloves greatly reduce the risk of cuts and lacerations, which are among the most common workplace injuries.

In hazardous settings, the availability of cut-resistant gloves empowers workers, allowing them to carry out their tasks with confidence, knowing they are shielded from potential injuries. This sense of security encourages a more focused and effective workforce, thereby decreasing the likelihood of accidents that could lead to serious injuries or fatalities.

Furthermore, adopting cut-resistant gloves can foster a culture of safety within the organisation, where employees feel valued and protected. This culture not only benefits the workforce but also enhances the company’s reputation as a responsible employer committed to safeguarding its employees.

Adherence to Health and Safety Regulations

Utilising cut-resistant gloves is a critical strategy for businesses striving to comply with health and safety regulations. The UK’s Health and Safety Executive (HSE) mandates that employers provide suitable PPE, including cut-resistant gloves, to protect workers from workplace hazards. Non-compliance can lead to significant legal repercussions, including fines and increased insurance premiums.

By investing in quality cut-resistant gloves that meet or exceed safety standards, employers can avert potential legal issues while ensuring a safe working environment. Compliance not only protects employees but also mitigates the risk of costly legal claims arising from workplace injuries.

Additionally, promoting a culture of safety can boost employee morale, resulting in increased productivity and job satisfaction. Workers who feel safe and valued are more likely to remain loyal to their employers, reducing turnover and associated costs.

Boosted Worker Confidence and Productivity

The assurance of safety provided by cut-resistant gloves directly correlates with heightened worker confidence and productivity. When employees know they are protected from potential injuries, they can focus on their tasks without the constant worry of accidents. This confidence often translates into improved performance, as workers are more inclined to engage fully in their roles.

Employers frequently observe that providing adequate safety gear, including cut-resistant gloves, leads to increased job satisfaction among employees. When workers feel secure, their overall attitudes toward their work improve, creating a more positive workplace atmosphere. The resultant boost in productivity can have a significant impact on a business's bottom line.

Moreover, instilling a sense of security can encourage employees to take on new challenges and responsibilities, further driving innovation and growth within the organisation.

Reduction in Workplace Accidents and Associated Costs

Investing in cut-resistant gloves not only enhances safety but also significantly decreases costs by reducing the frequency of workplace accidents. Cut injuries can lead to considerable medical expenses and lost time due to recovery and rehabilitation. By equipping employees with the appropriate protective gear, companies can effectively minimise the occurrence of such accidents.

A reduction in workplace accidents directly correlates with lower liability costs and potential legal claims. When workers are less likely to sustain injuries, businesses can avoid costly lawsuits and insurance claims, leading to long-term financial benefits.

Furthermore, maintaining a safe working environment can enhance an organisation’s reputation, attracting top talent and retaining skilled workers. Employees are more likely to select and stay with companies that prioritise safety, further contributing to the organisation’s success.

Maximising the Effectiveness of Cut-Resistant Gloves

Best Practices for Wearing Gloves

To ensure maximum effectiveness and safety, it is essential to wear cut-resistant gloves properly. Gloves should cover the entire hand and wrist, protecting vulnerable areas. Loose-fitting gloves may impede dexterity and increase the risk of accidents, as they can get caught on tools or equipment. Therefore, achieving a snug fit is imperative.

Before commencing any task, users should double-check that the gloves are intact and fit correctly. When donning gloves, ensure the cuff is properly positioned around the wrist to prevent exposure and allow for greater movement.

Additionally, consider the specific tasks being performed; if they involve heavy lifting or intricate work, gloves that provide both cut resistance and dexterity are vital. Proper wearing techniques not only enhance safety but also enable workers to perform their jobs more efficiently.

When Is It Essential to Wear Cut-Resistant Gloves?

Cut-resistant gloves should be worn whenever handling sharp objects or operating in environments where cuts pose a risk. This spans a variety of tasks, including cutting, slicing, handling glass or metal, and working with sharp tools. Ensuring gloves are consistently worn during such activities greatly diminishes the risk of injury.

In sectors such as construction, manufacturing, and food processing, the use of cut-resistant gloves is not merely a recommendation but an obligation. Employees should receive training to recognise when gloves are necessary, reinforcing the importance of personal safety in their daily tasks.

Furthermore, organisations should enforce the use of cut-resistant gloves as part of their safety protocols, ensuring that all employees adhere to best practices. By cultivating a culture of safety, businesses can protect their workforce while promoting continual awareness of workplace hazards.

How to Respond to Glove-Related Emergencies?

In the event of a glove-related emergency, such as a tear or cut, it is crucial to take immediate action. The first step is to cease work and evaluate the situation. If the glove has sustained significant damage, it should be replaced to maintain ongoing protection.

If a worker suffers a cut or injury due to a faulty glove, they should seek medical attention promptly. Documenting the incident is also essential for compliance and safety analysis.

Implementing a protocol for addressing glove-related emergencies can further enhance workplace safety. Training employees to identify glove damage and the procedures for reporting issues can lead to quicker resolutions and improved safety outcomes.

Common Uses of Cut-Resistant Gloves

Application in the Food Processing Sector

In the food processing industry, cut-resistant gloves are vital for preventing injuries while upholding hygiene standards. Employees working with knives and sharp utensils require reliable protection to avoid lacerations. Gloves specifically designed for food processing not only provide cut resistance but are often made from materials that are easy to clean and comply with food safety regulations.

Tasks such as cutting meat, slicing fruits and vegetables, and handling sharp tools necessitate the use of cut-resistant gloves. The advantages of using gloves in this context are evident; they shield workers from injury while also minimising the risk of contamination, ensuring that food products remain safe for consumption.

Employers in the food sector are increasingly recognising the importance of outfitting staff with cut-resistant gloves, both for compliance with health and safety standards and to nurture a culture of safety that enhances employee morale.

Usage in Construction and Manufacturing

Cut-resistant gloves are crucial in construction and manufacturing, where workers frequently encounter sharp tools and materials. The nature of these environments presents numerous hazards, making it essential to provide employees with dependable protective gear to avert injuries.

In construction, workers dealing with materials like sheet metal, glass, and sharp tools are particularly susceptible to cuts and lacerations. Cut-resistant gloves act as a crucial barrier, enabling workers to complete their tasks safely while reducing the risk of accidents. Similarly, in manufacturing, employees often handle machinery and sharp components, rendering the use of cut-resistant gloves a vital aspect of workplace safety protocols.

Employers in these sectors gain significant advantages from investing in high-quality cut-resistant gloves, as they help to decrease the frequency of accidents, lower insurance costs, and boost employee productivity.

Utilisation in Glass and Metal Handling

Handling glass and metal poses substantial risks due to their sharp edges and surfaces. Cut-resistant gloves are essential in these environments, providing the necessary protection against cuts and lacerations. Workers in the glass manufacturing and metal fabrication sectors frequently handle sharp materials, making cut-resistant gloves an indispensable safety requirement.

These gloves not only protect against injuries but also enhance the worker's grip and control when handling materials. This is especially critical when manoeuvring large sheets of glass or sharp metal components, where precision is paramount.

Employers in the glass and metal handling industries should prioritise the use of cut-resistant gloves to foster a safer work environment. By equipping employees with suitable PPE, businesses can significantly mitigate the risk of workplace injuries, leading to cost savings and increased employee satisfaction.

What Is the Cost of Cut-Resistant Gloves in London?

Understanding the Pricing for Various Types of Gloves

The cost of cut-resistant gloves in London varies considerably based on factors such as material, level of protection, and brand. Basic cut-resistant gloves can start at around £10, while more advanced options offering higher levels of protection can exceed £50.

For example, gloves crafted from Kevlar typically occupy the higher end of the pricing spectrum due to their durability and effectiveness. Conversely, Dyneema gloves, which provide a balance of cut resistance and comfort, may fall into the mid-range, generally priced between £15 and £30.

Understanding the price range can aid businesses and individuals in making informed choices when investing in protective gear. It is crucial to consider not only the initial cost but also the long-term value of reliable, durable gloves that provide the necessary protection.

Where to Discover the Best Prices on Cut-Resistant Gloves

Finding the best prices on cut-resistant gloves entails comparing costs from various sources, including local safety equipment stores, online retailers, and industrial suppliers. Local outlets such as Screwfix and Toolstation often feature promotions and discounts, making it worthwhile to check their offerings regularly.

Online retailers like Amazon UK and SafetyGloves.co.uk frequently provide competitive pricing along with occasional sales or discounts. Additionally, bulk purchasing options from industrial suppliers can yield significant savings, particularly for businesses aiming to equip multiple employees with protective gear.

To summarise, consider these top locations for securing deals on cut-resistant gloves:

- Screwfix

- Toolstation

- Amazon UK

- SafetyGloves.co.uk

- eBay

- Weldas UK

- RS Components

- Local safety equipment shops

By exploring various purchasing options, consumers can achieve the best value for their investment in cut-resistant gloves.

Factors Influencing the Cost of Cut-Resistant Gloves

Several factors influence the cost of cut-resistant gloves, with material composition, level of protection, and brand reputation being the most significant. The choice of material plays a critical role in determining the price; gloves made from advanced synthetic fibres or steel mesh tend to be more expensive due to their enhanced protective features.

The level of cut resistance, as specified by the EN 388 standard, also impacts pricing. Higher-rated gloves that provide superior protection generally command higher prices. Brand reputation can further influence cost, as established brands known for quality and reliability may charge a premium.

Moreover, whether gloves are sold individually or in bulk can significantly affect pricing. Bulk purchases often result in discounts, making it more economical for businesses to equip multiple employees with necessary protective gear.

Average Pricing for Cut-Resistant Gloves in London

On average, cut-resistant gloves in London cost between £20 and £30. This price point strikes a balance between affordability and the level of protection required for most tasks. At this price, users can find a variety of options that meet safety standards while providing adequate comfort and durability.

Investing in gloves within this price range ensures individuals and businesses can provide their employees with effective protective gear that supports workplace safety and compliance with health regulations. By researching options and understanding the market, consumers can make informed decisions that reflect both their safety needs and budgetary constraints.

Key Recommendations and Insights for Effective Usage

Essential Takeaways Regarding Cut-Resistant Safety Gloves

Cut-resistant safety gloves are critical for safeguarding against cuts and lacerations across various industries. By understanding different glove types, materials, and fit requirements, users can greatly enhance workplace safety. The commitment to equipping employees with suitable PPE is not merely a legal obligation but also a moral responsibility that fosters a culture of safety.

It is vital to consider the unique hazards of your work environment when selecting gloves, ensuring they meet the required standards for cut resistance and durability. Prioritising comfort and fit will further enhance the effectiveness of these gloves, allowing workers to perform their tasks safely and efficiently.

What Key Factors Should You Consider When Purchasing Cut-Resistant Gloves?

When acquiring cut-resistant gloves, several key factors warrant consideration. First, evaluate the necessary level of cut resistance for your specific tasks, using the EN 388 standard as a reference. Next, assess the material to ensure it aligns with your environmental and comfort requirements.

It is crucial to pay attention to sizing and fit, as improperly fitting gloves can compromise safety. Always choose reputable brands that comply with safety standards, and consider reading customer reviews for insights into performance and durability.

Finally, remain mindful of your budget; while investing in high-quality gloves may seem expensive initially, the long-term benefits of protecting workers and reducing accidents far outweigh the costs.

Final Recommendations for Safe and Effective Use of Gloves

To ensure the safe and effective use of cut-resistant gloves, adhere to these final recommendations. Always wear gloves correctly, covering the entire hand and wrist to provide maximum protection. Regularly inspect gloves for signs of wear and tear, and replace them immediately if damaged.

Following the manufacturer’s maintenance and care guidelines will extend the lifespan of your gloves. Cultivating a culture of safety in your workplace by encouraging employees to prioritise the use of gloves whenever handling sharp objects is essential. By implementing these practices, you can significantly enhance safety and efficiency in your work environment.

Frequently Asked Questions About Cut-Resistant Gloves

What materials are typically used in cut-resistant gloves?

Cut-resistant gloves are commonly constructed from materials such as Kevlar, Dyneema, or stainless steel mesh, each offering varying levels of protection and comfort.

How can I determine the correct size for cut-resistant gloves?

To ascertain the right size, measure your hand using the manufacturer’s sizing charts and try on different sizes to find the best fit.

Are cut-resistant gloves waterproof?

Most cut-resistant gloves are not waterproof. However, certain models may offer water resistance, making them suitable for specific tasks in wet environments.

Can I wash cut-resistant gloves?

Yes, many cut-resistant gloves can be washed. Follow the manufacturer’s cleaning instructions to maintain the integrity and effectiveness of the product.

What is the typical lifespan of cut-resistant gloves?

The lifespan of cut-resistant gloves varies depending on usage and maintenance, but they can last several months to a year if properly cared for.

Do cut-resistant gloves provide thermal protection?

Some cut-resistant gloves offer thermal protection, but it is essential to check the specifications before use, as not all gloves are designed for heat resistance.

Are there regulations concerning the use of cut-resistant gloves?

Yes, the UK’s Health and Safety Executive mandates the use of appropriate PPE, including cut-resistant gloves, to protect workers from workplace hazards.

Can cut-resistant gloves be used for all tasks?

Cut-resistant gloves should be worn when handling sharp objects. However, different tasks may require specific glove types, so assess your needs carefully.

How can I enhance the grip of cut-resistant gloves?

Many cut-resistant gloves feature textured surfaces to improve grip. If grip is a concern, consider selecting gloves specifically designed for enhanced handling.

Where can I purchase cut-resistant gloves in London?

Cut-resistant gloves can be acquired at local safety equipment stores, online retailers, or industrial supply companies throughout London, providing various purchasing options.

Connect with us on Facebook!

The Article: Buy Cut Resistant Safety Gloves in London: Your Essential Guide first published on https://www.gloveclub.co.uk

The Article Cut Resistant Safety Gloves: Essential Buying Guide for London Was Found On https://limitsofstrategy.com