Your Comprehensive Guide to PPE Masks and Visors in the UK

What Are the Primary Materials Used in PPE Masks Throughout the UK?

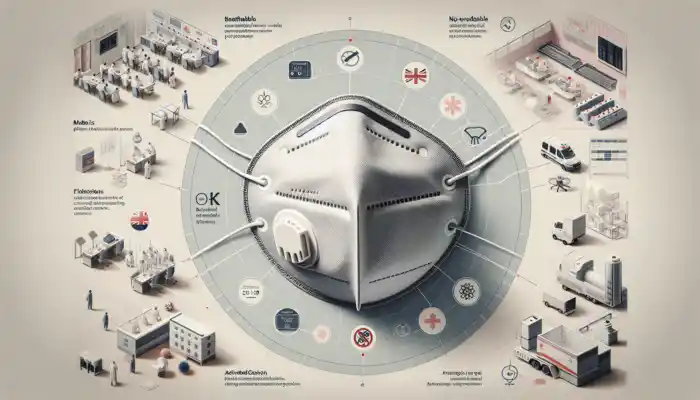

In the UK, PPE masks and visors are crafted from a selection of materials, each selected for its specific properties that fulfil the demands of various environments and user needs. One of the most prevalent materials is nonwoven polypropylene, renowned for its remarkable filtration capabilities and breathability, which significantly increases comfort for the user during extended wear. Additionally, certain masks include activated carbon layers that provide enhanced protection against unpleasant odours and harmful airborne particles. Adherence to British standards, including EN 149 for filtering half masks, guarantees that these materials undergo stringent testing to confirm their durability and safety against a variety of hazards. This assurance makes them ideal for a diverse range of sectors, including healthcare and construction, ensuring effective protection in various working conditions.

Critical Design Features for Optimal Performance of Visors

High-performance visors in the UK are meticulously designed to fulfil strict criteria that ensure maximum protection for users. Essential features mandated by UK regulations include fog resistance, which is vital for maintaining clear visibility in settings such as healthcare and industrial environments. An effective fit around the forehead and chin is necessary to prevent exposure to hazardous substances. Furthermore, the visor material must exhibit scratch resistance and provide an unobstructed field of vision, conforming to local safety standards, which allows users to carry out their tasks efficiently without obstruction. These design principles not only bolster overall performance but also significantly reduce risks associated with workplace hazards, thus promoting a safer environment for all employees.

How Can You Effectively Choose the Right PPE for Your Workplace in the UK?

Choosing the appropriate PPE for workplaces in the UK necessitates a thorough understanding of the specific hazards present in the environment. Key criteria to take into account include:

- User comfort: It is essential that the PPE can be worn over long periods without causing discomfort or distraction to the wearer.

- Compatibility: Ensure that the PPE integrates seamlessly with existing safety equipment, including helmets or goggles, for comprehensive protection.

- Compliance: Adherence to UK regulatory standards is vital to ensure sufficient protection against identified workplace hazards, thereby effectively safeguarding employees.

- Ease of maintenance: Consider the maintenance and cleaning processes required to prolong the lifespan of the PPE, ensuring it remains effective over time.

By prioritising these factors, employers can ensure that the selected PPE meets compliance requirements while significantly improving the safety and efficiency of their workforce, ultimately leading to a more productive and secure working environment.

Diving into the Various Types of PPE Masks and Visors Offered in the UK

What Are the Standard Mask Varieties Typically Found in the UK?

In the UK, the standard varieties of masks encompass disposable surgical masks and fabric face coverings. Disposable masks are commonly used in numerous public and healthcare environments, providing a fundamental level of protection against respiratory droplets and airborne particles. Compliance with national health guidelines ensures these masks are effective for general use, especially during health emergencies. Conversely, fabric masks offer a more sustainable choice, permitting custom designs while ensuring they meet essential filtration standards. The selection of appropriate masks should correspond with specific usage scenarios, guaranteeing they are fit for purpose and effectively mitigate associated risks across various contexts.

What Advanced Visor Options Are Accessible for UK Industries?

Advanced visor options are specifically engineered for UK industries, featuring specialised attributes that cater to high-risk environments, such as those encountered by emergency services and manufacturing sectors. These visors often come equipped with anti-fog coatings and improved impact resistance, ensuring compliance with UK regulatory standards. For example, firefighter visors are constructed from materials capable of withstanding extreme heat, markedly enhancing user safety during critical operations. By implementing these advanced visors, employers can ensure their workforce is adequately protected against occupational hazards, fostering a culture of safety across various industries and work environments.

How Can You Customise PPE Masks and Visors in the UK?

Customisation of PPE masks and visors in the UK is crucial for addressing individual user requirements while ensuring compliance with regulatory guidelines. Effective steps for adapting PPE involve conducting comprehensive user assessments to identify specific needs, selecting adjustable components to enhance fit and comfort, and ensuring adherence to relevant safety standards during modifications. Employers can collaborate with PPE suppliers to develop tailored solutions that improve user safety and comfort while sustaining protective capabilities. Such adaptability guarantees that PPE remains effective across various job roles, accommodating the unique demands of each workplace and enhancing overall safety.

What Factors Influence the Suitability of PPE Masks?

What Key Elements Impact Mask Fit in the UK?

Determining the suitability of PPE masks depends on several vital factors that influence fit, which is essential for effective protection. Key tests, including seal checks and user trials, are conducted to confirm that masks comply with UK standards for proper fit. A fit test should ensure that no air leaks occur around the edges during normal movement, thereby guaranteeing maximum protection. Regular assessments are particularly important, especially when masks are worn for extended periods or in high-risk environments. Ensuring a proper fit not only enhances user comfort but also maximises the mask’s protective capabilities, thereby fulfilling the stringent requirements set out in UK regulations and safeguarding the user's health.

How Can You Evaluate Visor Clarity for Effective Use in the UK?

The clarity of visors is crucial for ensuring safety during various tasks, particularly in sectors such as healthcare and construction. Assessments should focus on how the visor’s optical quality aligns with UK visibility needs, determining whether it meets the necessary standards for safe operation. A clear, distortion-free visor is essential, as it enables users to perform intricate tasks without visual obstructions. Adherence to UK standards for optical clarity is critical in preventing accidents that may arise from impaired vision. Regular inspections and maintenance of these visors are recommended to preserve clarity and ensure they remain fit for purpose, especially in high-stakes environments.

Why is Compatibility with Other UK Safety Gear Crucial?

The compatibility of masks and visors with other safety gear is essential to ensure comprehensive protection in the UK workplace. Masks must seamlessly integrate with helmets, goggles, and other PPE to avoid compromising overall safety. Guidance on achieving this compatibility includes selecting masks designed to work in conjunction with specific helmet types, ensuring that straps do not interfere with the helmet’s fit. Similarly, visors should be compatible with eyewear to prevent gaps that could expose workers to potential hazards. By focusing on compatibility, employers can establish a holistic safety strategy that adheres to workplace regulations, ultimately enhancing the overall safety and effectiveness of their protective equipment.

Expert Insights on PPE Masks and Visors: Suitability and Compliance with Regulations

What Do Experts Recommend Regarding Mask Performance in the UK?

Real-world examples from UK studies highlight the necessity of evaluating mask performance to ensure compliance with regulatory requirements. Research has demonstrated that specific surgical mask models provide superior filtration efficacy, which is vital for frontline workers in high-risk environments. When selecting masks, it is essential to consider aspects such as breathability and user comfort, as prolonged use can affect overall effectiveness. Actionable steps include consulting suppliers for data on mask performance under defined conditions and ensuring that selected models align with the latest guidelines from health authorities, thus maximising user protection and safety.

What Should You Understand About Regulatory Compliance for Visors?

Navigating the complexities of visor standards in the UK requires a comprehensive understanding of regulatory compliance. The first step is to ensure that visors are certified in accordance with national guidelines, which mandate rigorous testing for impact resistance and clarity. Regular inspections are essential to maintain compliance, and these should be scheduled at defined intervals to identify any wear and tear that may compromise safety. Additionally, engaging with professional organisations can provide valuable insights into best practices for maintaining visor efficacy and ensuring regulatory compliance, ultimately enhancing user safety across sectors and ensuring compliance with existing standards.

How Can You Implement Advanced Suitability Testing Methods for PPE?

Understanding advanced suitability testing methods for PPE is crucial in the UK to ensure ongoing compliance with regulatory requirements. UK-approved testing protocols focus on evaluating factors such as filtration efficiency, breathability, and resistance to liquid penetration. Regular audits of PPE performance against these protocols help identify any shortcomings and ensure that the equipment continues to deliver effective protection. Engaging in continuous education regarding emerging testing methods enhances users’ ability to select suitable PPE that meets or exceeds current regulations, thereby supporting a proactive approach to workplace safety and effectively protecting the workforce.

What Are the Fundamental Regulatory Requirements for PPE in the UK?

What Are the Key UK Laws Governing PPE Masks?

In the UK, the primary legislation governing PPE masks is the Personal Protective Equipment at Work Regulations 1992. This regulation outlines essential requirements for masks, ensuring they are suitable for their intended use, particularly in sectors such as healthcare, where contamination risks are notably elevated. Employers are tasked with selecting appropriate masks that comply with these regulations, highlighting the need for thorough risk assessments to determine specific needs. Adhering to these laws not only protects workers but also mitigates legal liabilities associated with non-compliance, thereby creating a safer working environment for all.

What Standards Must Be Met for Visor Certification in the UK?

Visor certification standards in the UK are critical for ensuring safety and effectiveness across various applications. Compliance with EN 166, the standard for personal eye protection, necessitates rigorous testing for factors such as impact resistance, optical quality, and durability. Manufacturers must demonstrate that their visors meet these benchmarks before they can be marketed for workplace use. Regular audits and updates to these standards are essential to ensure that visors remain effective against evolving hazards, thereby safeguarding users in high-risk environments and ensuring compliance with health and safety regulations.

What Are the Consequences of Non-Compliance with UK PPE Regulations?

Failure to adhere to PPE regulations in the UK can result in substantial penalties, which may include:

- Fines for non-compliance with established safety standards.

- Legal action stemming from workplace injuries linked to insufficient PPE provisions.

- Increased insurance premiums due to recognised safety infractions and non-compliance.

- Potential criminal charges against employers for gross negligence in ensuring worker safety.

Prioritising regulatory compliance is crucial for employers to protect their workforce and avoid the detrimental consequences of non-compliance, thus ensuring a safer working environment for all employees.

What Standards Govern Protective Gloves in the UK?

Protective gloves in the UK must comply with key regulations that dictate their material strength, chemical resistance, and ergonomic design. These standards are essential for safeguarding workers, particularly in sectors such as manufacturing and healthcare, where exposure to hazardous substances is prevalent. Compliance with EN 420 and EN 374 ensures that gloves provide the necessary protection while also maintaining user comfort and dexterity. Regular assessments and updates to glove standards help ensure ongoing compliance, enhancing worker safety across a range of industries and reducing the risk of accidents.

Research-Backed Benefits of PPE Masks and Visors: Suitability and Compliance with Regulations

What Evidence Supports the Suitability of PPE for UK Health Workers?

A multitude of studies has emphasised the advantages of PPE masks for UK health workers, highlighting their vital role in infection control. Research indicates that the utilisation of high-quality masks significantly diminishes the risk of airborne transmission, particularly during procedures that generate aerosols. Concrete examples include hospitals that have adopted specific mask types, leading to reduced infection rates among healthcare personnel. Regulatory compliance amplifies these protective measures, ensuring that masks are not only effective but also meet the standards established by health authorities, thereby safeguarding the health of both workers and patients.

What Advantages Do Visors Offer in Educational Settings in the UK?

In educational environments, the adoption of visors presents distinct benefits, particularly in maintaining safety during teaching activities. Research reveals that visors can effectively decrease the transmission of respiratory droplets while promoting clear communication, which is vital in classrooms. Adherence to national safety mandates is crucial, as many schools have incorporated visors into their safety protocols. Continuous evaluation of visor efficacy in educational settings underscores the importance of complying with regulatory requirements to ensure the safety of both staff and students, fostering a secure learning atmosphere.

What Long-Term Benefits Are Associated with Proper Regulation of PPE?

Effective regulation of PPE in the UK promotes long-term benefits that extend beyond immediate safety concerns. By adhering to established standards, employers can cultivate a culture of safety that minimises workplace accidents and injuries. Ongoing training and education regarding PPE compliance ensure that workers remain informed about best practices, contributing to a sustainable safety strategy. Actionable steps include regularly reviewing PPE policies and engaging with regulatory bodies to stay updated on any changes, thereby maintaining compliance and enhancing the overall effectiveness of workplace safety measures.

How Do Regulations Influence PPE Suitability?

How Have Recent UK Updates Influenced Mask Design?

Recent updates to UK regulations have profoundly impacted mask design, particularly concerning filtration efficiency and user comfort. Regulatory bodies have responded to health crises by mandating enhancements in mask materials, prompting manufacturers to innovate and improve protective features. For instance, current regulations encourage the adoption of multi-layer designs that boost filtration without sacrificing breathability. Such adaptations ensure that masks remain suitable for prolonged use, align with the evolving needs of various sectors, and effectively address public health challenges.

What Are the Regulatory Impacts on Visor Durability?

The UK regulatory framework plays a crucial role in enhancing visor durability. Updated standards have encouraged manufacturers to utilise higher-quality materials that can withstand regular use, ensuring that visors remain effective over time. Compliance with these standards is essential to guarantee that visors can endure the conditions typical in high-risk environments, such as construction sites or healthcare facilities. By prioritising durability through regulatory compliance, employers can significantly improve the suitability of visors for daily use, contributing to long-term safety and protection for workers across industries.

How Can You Balance Cost and Compliance in the UK?

Achieving regulatory compliance without compromising PPE suitability necessitates careful planning and resource allocation. Key strategies to facilitate this balance include:

- Investing in bulk purchases to reduce costs while ensuring quality compliance with safety standards.

- Conducting regular training sessions to educate staff on PPE selection, usage, and maintenance.

- Utilising government resources or subsidies available for safety equipment to alleviate financial burdens.

- Engaging with reputable suppliers who prioritise compliance in their offerings, ensuring the highest safety standards for PPE.

By concentrating on these strategies, employers can maintain an effective balance between cost management and compliance with safety regulations, ultimately enhancing overall workplace safety and ensuring the well-being of their workforce.

Guidelines for Maintaining and Disposing of PPE in the UK

What Are the Recommended Cleaning Protocols for PPE Masks?

Implementing comprehensive cleaning protocols for PPE masks is essential to ensure their ongoing suitability in the UK. Masks must be regularly disinfected in accordance with environmental guidelines to avert cross-contamination. Recommended methods include using alcohol-based sanitising solutions or laundering fabric masks at elevated temperatures to effectively eradicate pathogens. Regular maintenance not only extends the lifespan of the masks but also protects users’ health, ensuring they remain effective at guarding against airborne hazards and minimising the risk of infection across various environments.

What Are the Correct Disposal Methods for Visors in the UK?

Proper disposal of visors is vital to comply with UK waste regulations and prevent environmental hazards. Eco-friendly disposal methods encompass recycling plastic components whenever feasible and ensuring that contaminated visors are discarded in designated hazardous-waste bins. Employers should establish clear disposal protocols to educate staff on safe practices that mitigate environmental impact while adhering to local regulations. By prioritising proper disposal, organisations can contribute to sustainability efforts while maintaining regulatory compliance, thereby promoting a cleaner, safer environment.

How Can You Ensure Proper Storage for PPE Longevity?

To preserve the suitability of masks and visors, implementing proper storage solutions is crucial. PPE should be stored in cool, dry environments, shielded from direct sunlight and potential contaminants to prevent degradation. Using clearly labelled containers can facilitate effective organisation of PPE, ensuring easy access while maintaining cleanliness and order. Furthermore, conducting regular inventory checks can help identify items that require replacement before they become unsuitable for use. By adhering to these storage guidelines, organisations can extend the lifespan of their PPE, ensuring it remains effective and ready for use when required.

Why Are PPE Inspection and Maintenance Schedules Essential?

Regular inspections of PPE, including masks and visors, are critical for early identification of any damage and ensuring compliance with UK health and safety regulations, such as those outlined by the HSE. Establishing a robust maintenance schedule that includes visual checks for wear and tear and functional assessments enhances ongoing effectiveness and user safety. Documenting these inspections is vital to demonstrate compliance and improve accountability within the organisation. By prioritising inspection schedules, employers can uphold high safety standards and ensure their workforce remains protected from workplace hazards.

What Future Trends Are Emerging in PPE Regulations in the UK?

What Innovations Are Influencing the Future of Mask Technology?

The landscape of mask technology in the UK is rapidly evolving, with emerging trends concentrating on enhancing suitability and compliance with regulatory frameworks. Innovations such as smart masks equipped with sensors to monitor air quality and filter efficiency are gaining popularity. These advancements not only enhance user safety but also align with the increasing demand for data-driven solutions in health and safety practices. As regulations adapt to accommodate these new technologies, stakeholders must remain informed to ensure that new products meet established standards and provide the necessary protection for users.

How Are Visor Standards Adapting in the UK?

Future regulations are likely to significantly influence the development of visors, with a focus on enhancements that improve user protection across various settings. Anticipated changes may include stricter standards for impact resistance and the introduction of new materials that enhance clarity and durability. Manufacturers will need to swiftly adapt to these evolving standards to maintain compliance and ensure that their products remain suitable for a wide array of applications. Staying informed about these changes is critical for all stakeholders to ensure ongoing workplace safety and compliance, ultimately safeguarding the workforce more effectively.

What Potential Changes to PPE Compliance Rules Should We Anticipate?

Expected shifts in UK laws concerning PPE compliance could significantly impact the overall suitability of masks and visors. As public health priorities evolve, regulatory bodies may update existing standards, necessitating manufacturers to enhance product efficacy and safety. Stakeholders should prepare for potential changes by engaging in continuous education on compliance requirements and investing in adaptive solutions that align with future regulations. This proactive approach will help ensure that PPE remains not only compliant but also effective in shielding the workforce against emerging risks and health challenges.

FAQs: Key Questions Regarding PPE Masks and Visors

What Are the Various Types of PPE Masks Available in the UK?

The UK offers an array of PPE masks, including disposable surgical masks, FFP respirators, and reusable fabric masks, each designed for specific applications and tailored to varying levels of protection based on user needs.

How Do I Select the Appropriate PPE Visor for My Workplace?

Choosing the right PPE visor necessitates assessing the specific risks associated with your workplace, ensuring compliance with established safety standards, and selecting features such as anti-fog coatings and impact resistance to bolster user safety.

What Regulatory Standards Must PPE Masks and Visors Meet in the UK?

PPE masks and visors in the UK must conform to standards established by regulatory bodies, such as EN 149 for masks and EN 166 for visors, ensuring they provide adequate protection against identified workplace hazards.

How Frequently Should PPE Be Inspected and Maintained?

PPE should be regularly inspected, with a comprehensive maintenance schedule established to ensure masks and visors remain effective and compliant with applicable safety regulations, thereby safeguarding users’ health.

Can PPE Masks Be Reused, and What Are the Cleaning Procedures?

Certain PPE masks, such as fabric masks, can be reused after proper cleaning, which typically involves washing at high temperatures or utilising disinfectant sprays to effectively eliminate contaminants.

What Are the Implications of Non-Compliance with PPE Regulations?

Non-compliance with PPE regulations in the UK can lead to significant penalties, including monetary fines, legal actions, and increased insurance premiums, as well as heightened risks of workplace injuries linked to inadequate protective measures.

How Does Mask Fit Influence Its Effectiveness?

A proper fit is crucial to a mask’s effectiveness, as gaps can allow harmful contaminants to infiltrate, significantly diminishing its protective capabilities and potentially exposing users to serious health risks.

What Should I Do If My PPE Visor Becomes Damaged?

If your PPE visor sustains damage, replace it immediately to guarantee ongoing protection against hazards. Regular inspections can help identify damage early, averting the prolonged use of ineffective equipment that could compromise safety.

Are There Eco-Friendly Disposal Methods for PPE?

Yes, eco-friendly disposal methods for PPE involve recycling plastic components where feasible and disposing of contaminated items in designated hazardous waste bins to mitigate environmental impact and comply with local regulations.

What Trends Are Emerging in PPE Technology?

Emerging trends in PPE technology encompass the development of smart masks equipped with air-quality sensors and advanced materials that enhance filtration and comfort, reflecting the growing demand for innovative solutions in health and safety practices.

Connect with us on Facebook today!

The Article: PPE Masks and Visors: Suitability and Regulatory Needs first published on https://www.gloveclub.co.uk

The Article PPE Masks and Visors: Understanding Suitability and Regulations Was Found On https://limitsofstrategy.com